Adhesion

Adhesion is the interaction that develops between two dissimilar bodies when they are in contact. At the molecular level, adhesion is based on physical and in some cases chemical bonding. The strength of adhesion depends on the type of adhesive.

Pressure sensitive adhesives build up adhesion under light pressure. The ultimate bonding strength is reached after 24 ~ 72 hours.

Test method: “peel adhesion test” and "initial tack - rolling ball" . For specific data, please refer to TDS.

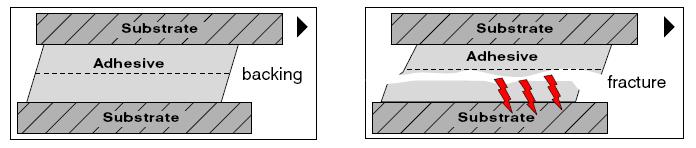

Adhesive failure describes the separation of adhesive either from backing or from the substrate. The other basic failure mechanism of an adhesive bond is “cohesive failure” which refers to a fracture in the middle of the bulk adhesive.

Adhesive

Adhesives are polymer materials that are used to join dissimilar materials. Adhesives may be classified in many ways, e.g. by mode of application and setting, chemical composition, cost, and suitability for various adherents and end products.

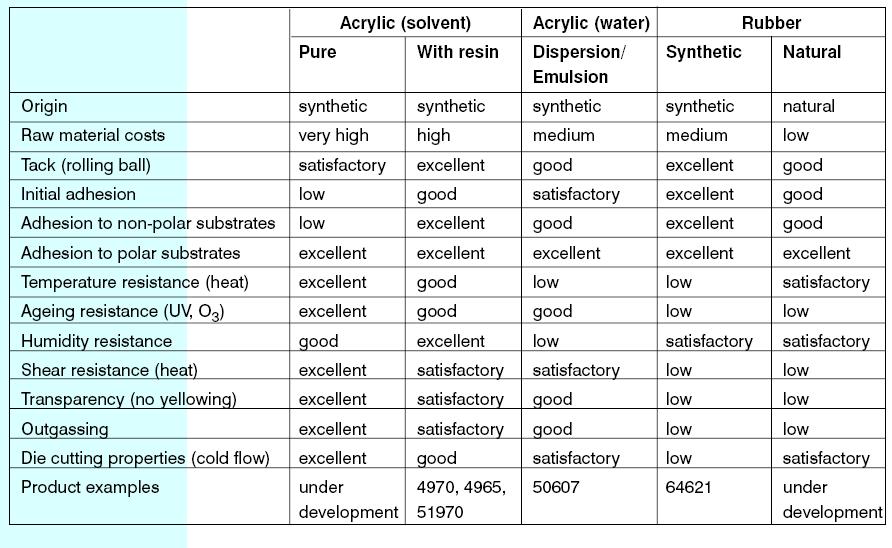

The term "pressure sensitive adhesive" (PSA) is used to describe adhesives that are permanently tacky in dry form at room temperature. The most common pressure sensitive adhesives are acrylics, natural rubber/resin, and synthetic rubber/thermoplastic rubber. For comparison of basic properties, please refer to the following table:

Ageing resistance

Degree of reliable performance of the tape over time, under certain conditions. Depending on the adhesive system being used, PSA tapes are often usable for permanent applications. This permanence is reflected by the resistance of the adhesive against:

- Ozone (O3), Oxygen (O2)

- UV light: relevant for transparent substrates such as glass or PC; under direct exposure, yellowing or discoloration of the adhesive or backing (e.g. window bars).

- Temperature - Humidity, water

- Different kinds of chemicals …

Generally acrylic adhesives are much better suited to withstand these environmental influences than rubber adhesives and can maintain their permanent, reliable functionality over many years.

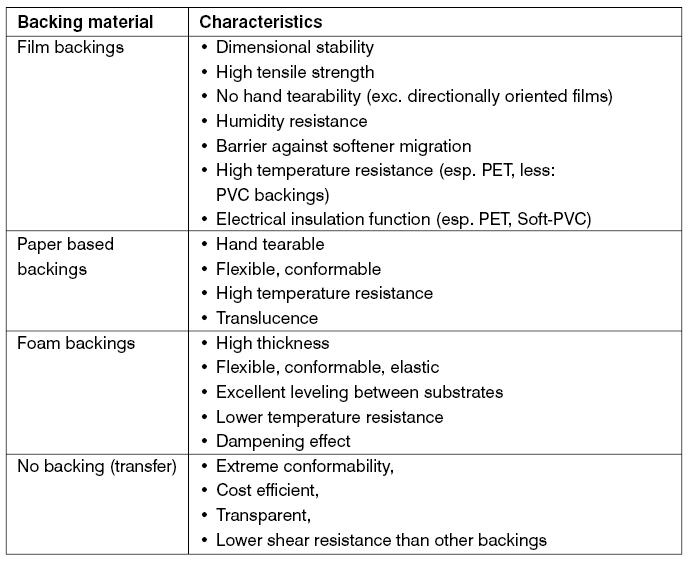

Backing

Materials which “carry” the adhesive. The backing also reinforces the PSA tape and improves handling and processing properties. Most commonly used backing types are:

1. Film backings (e.g. PET, PP, PVC, PE)

2. Paper based backings (e.g. non-woven, tissue)

3. Foam backings (e.g. PU-, PE-, PVC-foams)

4. Woven cloth (e.g.rayon, cotton, PA, PET) A specialty PSA tape type is a transfer PSA tape which has no backing. The adhesive is directly coated on the liner.

5. Other less typical backing materials are cloth, fabrics, metals etc. Overview of backing material characteristics:

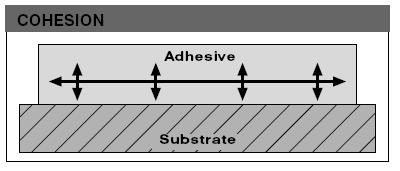

Cohesion

Cohesion describes the inner strength of the adhesive. It mainly determines the holding power (shear resistance of the tape. Test method: “shear resistance test”.

Cohesive failure leaves adhesive residue on both the PSA tape backing and the laminated surface, showing that the adhesive broke internally. Easy check with the finger: it sticks on both the substrate and the tape.

Basically: high cohesion = higher temperature resistance = lower tack = high holding power

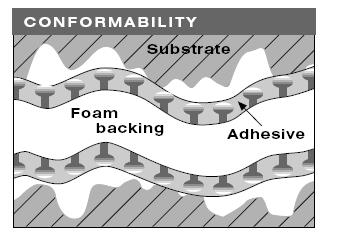

Conformability

The backing of a PSA tape influences its ability to adhere to curved, rough or irregular surfaces. Conformable backings increase the contact area of adhesive and substrate. Foam backings are inherently conformable and can therefore compensate for surface irregularities between the two bonding substrates.

Dimensional stability

Correlates with humidity of liners. Dimensional stability prevents the liner from showing an irregular surface or dimensional change due to absorption of moisture.

Dimensionally stable liners are mainly PE coated paper liners and Film liners.

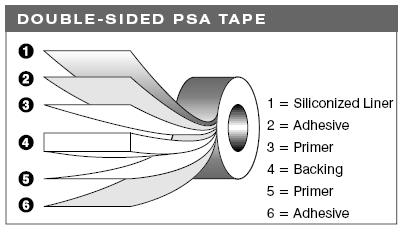

Double-sided tape

Comprised of a backing material coated with adhesive on both sides. Usually one adhesive layer is covered with a release liner (closed side) in order to wind the PSA tape in roll form. In d/s tape production the backing is often pre-treated with a primer to enable a maximum anchorage between backing and adhesive. Transfer tape.

Fish eyes

Optical effect caused by entrapment air between different tape layers on a roll.

Foam

Material containing small holes (cells) distributed throughout the entire body. Most common foams are:

-AC-foam Ethylene

-vinylacetate

-foam (EVA) Polyurethane

-foam (PU) Polyethylene-foam (PE)